Source

Terah wheat

On the shelf

Working together means moving forward. We strengthen the experience and expertise we share at Terah with insights that we keep developing in collaboration with our partners. That is growth we call profit. That is the recipe for products that link quality to sustainability.

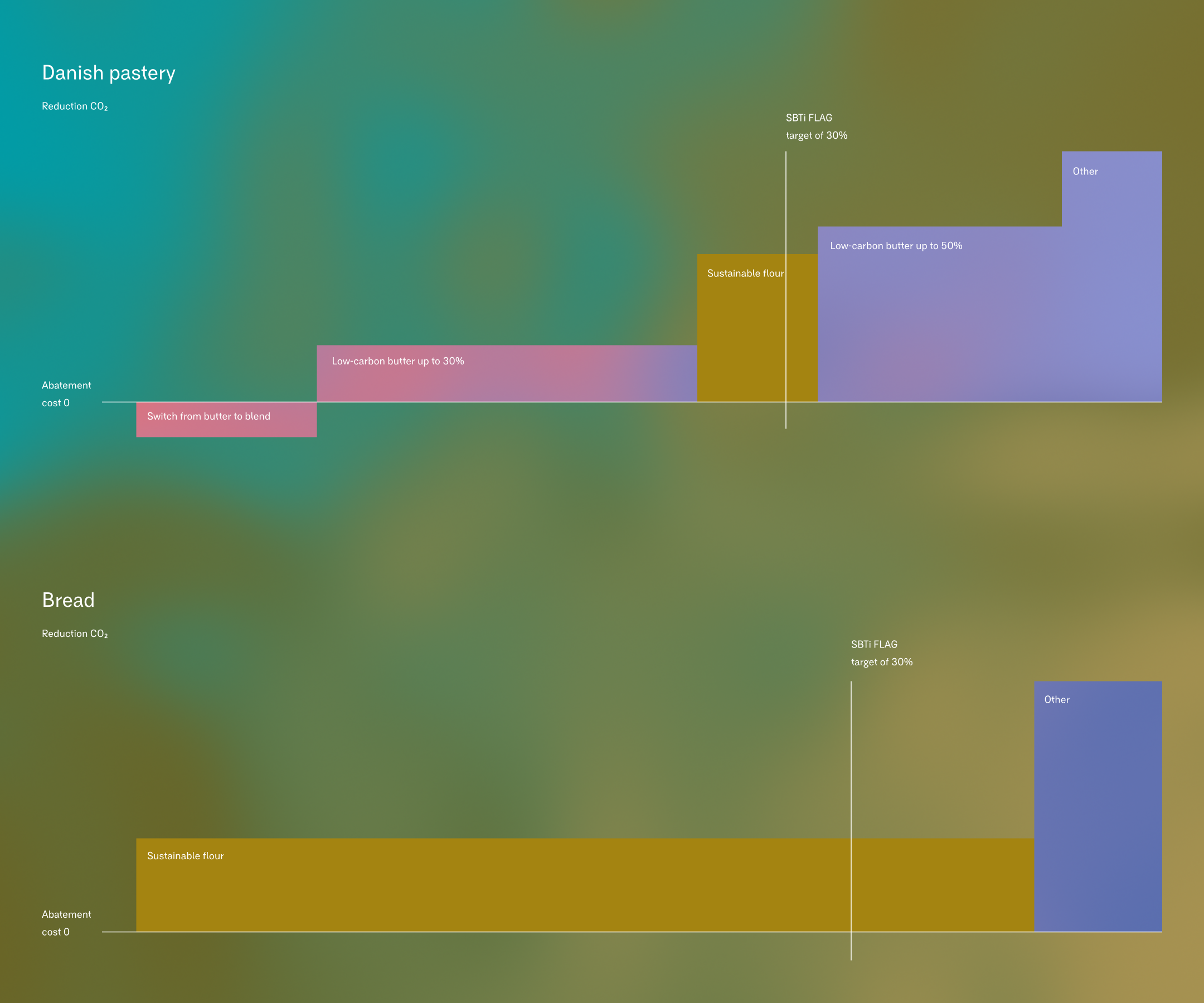

In the food chain ‘from farm to fork’, Terah places the emphasis on the cultivation of wheat. By reducing CO2 emissions on the field and improving CO2 storage, we make a significant difference in the ‘scope 3’ goals for the agro business. In addition, we also make tangible improvements to biodiversity and soil health.

Together, we make our ambitions tangible – from science research to sales revenue. Unlike margarine as a more sustainable alternative to butter, Terah flour does not differ in functionality or taste. It is an excellent alternative with a significant impact reduction.

True impact manifests itself on the field, but also on paper. Through the ‘Mass Balance’ approach, we can demonstrate the exact share of Terah wheat (net) at each step in the process. This gives our customers an accurate overview of our results. We truly commit to profit.

Terah wheat

Terah wheat

Terah wheat

Terah flour